- #Cnc simulator program download full#

- #Cnc simulator program download registration#

- #Cnc simulator program download verification#

- #Cnc simulator program download software#

- #Cnc simulator program download code#

#Cnc simulator program download registration#

SSNC sever saves students registration information and allows Students work on theĮxercise and transmit the answers back to the instructor. Including pictures to clients (students). Network the instructor can centrally manage, monitor and tutor theĪdd and edit exercises in SSCNC server. Once the student log in from any computer in a local Students are registered in the SSCNC server by means of a usernameĪnd password. Server-client configuration it provides the instructor with theĬapability for managing students, classes and tests.

#Cnc simulator program download software#

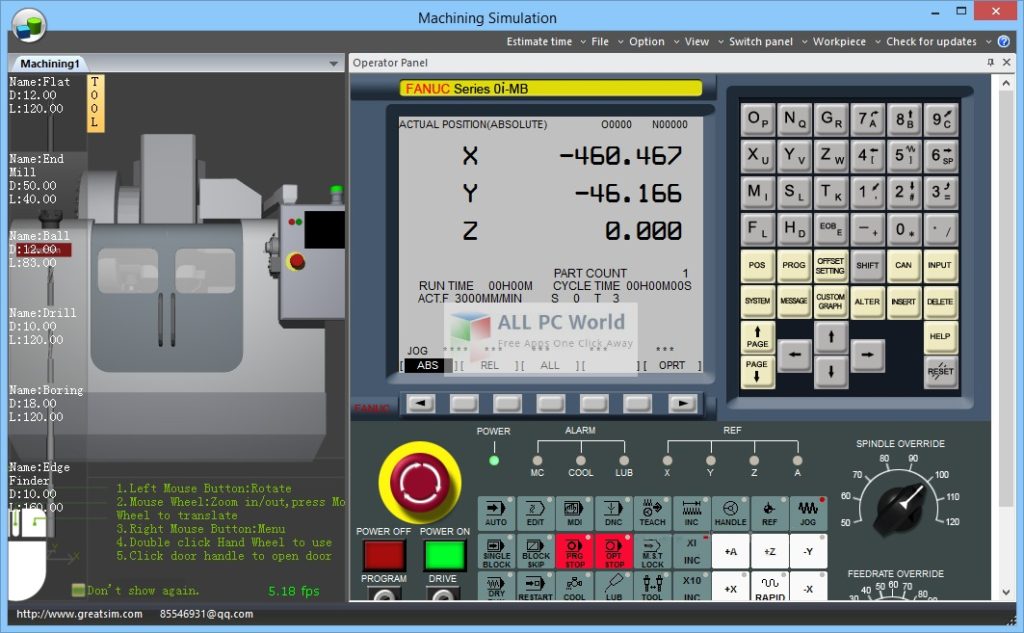

When the software is installed on a local network in a Performs all functions of the command operation, facilitating theĪdaptation of the student with the CNC equipment. Adjust the parameters of the virtual machine. Alarm collision with the piece, bench or other machine parts. Modes JOG, MDI, EDIT, SINGLE BLOCK, AUTOMATIC, DRY RUN, STOP Preset tool axes X and Z (Lathe) and height of tool Preset zero point G54, G55, G56, G57 etc … Simulates post processed files produced by UGS, Pro-E, Master

#Cnc simulator program download code#

Support for custom code and cycles in different NC systems. FANUC, SIEMENS polar coordinate programming, G02, G03 spiral Capability to simulate canned cycles, macros and the inclusion of Support ISO-1056 preparatory function codes (GĬodes), assistant function codes (M codes).

#Cnc simulator program download verification#

Program verification of canned cycles and language syntaxĪccording to the command code for the specific model. Changes in the lines of program are simple and intuitive. Edition capabilities (cut, copy, paste). Programs are easily created in ASCII format using any text Operation process recording and replay in AVI format. Windows MACRO recording and playback system. Use virtual measuring tools: edge finder, feeler gauge, The automatic tool changer for the machining center can be The turret can be configured for 4, 8 or 12 stations (front or Database management tools and tools customization. Materials library, edit and insert new materials. Roughness measurements based on tool cutting parameters. Three-dimensional measuring of workpiece after it is Offsets and the use of different clamping devices. Machine simulation includes real components like coolant, soundįor machining operations and chips generation. Operation mode for the machine and clearing all the alarms. Zeroing the workpiece, select and measure tools, select the right Total machining process simulation: selecting the workpiece, Realistic three-dimensional numerical control machine tools and Realistic control panels and operator panels.

#Cnc simulator program download full#

Dynamic rotation, zoom, pan, full screen and switch views during

The functionality of the simulator: preparation of texts of control programs of turning operations in the format of a standard GM code, checking control programs for syntax and technological errors, playing on the computer screen (or other computing device) three-dimensional graphic models of the main components of the lathe machine and metal-cutting tools to simulate the process of turning metal, the three-dimensional visualization of the process of forming parts during turning on the compiled control programs, visualization of toolpaths, implementation of interactive user interaction with the simulation model of technological equipment. Material processing is performed on two axes in the horizontal plane.įield of application of the software product: educational process using computer technology: laboratory lessons of students in computer classes, distance learning, demonstration support of lecture material in the group of areas of training and specialties: «Metallurgy, Engineering and Material Processing». The basis of the three-dimensional simulation model is a lathe with a classical arrangement of units, equipped with a CNC system, an eight-position turret, a three-jaw chuck, a tailstock, a coolant supply system and other machinery. A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard GM code (Fanuc System A).

0 kommentar(er)

0 kommentar(er)